Colloide Lamella Separator Packages part of £300M Project

Williamsgate WTW Project Overview

Williamsgate Water Treatment Works forms part of the £300M West Cumbria Water Supplies Project. This is a brand-new facility and its overall purpose is to help provide a resilient, sustainable water network for West Cumbria, which all began back in 2017. Once the wider network and infrastructure is complete, the site will be capable of treating 80 million litres of water every day when it’s completed in 2022.

A great final result will be achieved and Ian Tomlinson, Project Manager from United Utilities puts this down to great partnership working, not only with contractors but with process colleagues who will eventually operate the treatment works.

Colloides Lamella Systems

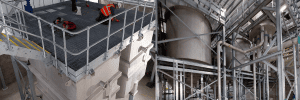

Colloide designed, supplied and commissioned the Williamsgate Water Treatment Works Lamella Separator packages. One system was installed as part of a potable water treatment plant and the other was required to treat filtrate from a sludge dewatering process. This was in partnership with Advance JV, for their client United Utilities.

Our Potable Water Lamella Separator Package

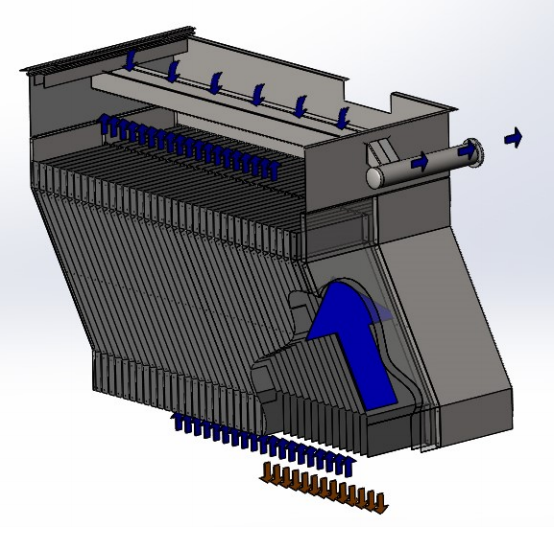

This system is a 3-stream system to handle a peak flow of 7,776m3/day (324m3/hr). Colloides package included a full set of stainless-steel Lamella Separators which are certified to DWI standards for use in public water supply in the United Kingdom. These were mounted within stainless steel tanks with flocculation tanks upstream of these separators. Sludge is collected under the Lamella Separators and concentrated up to 3% Dry Solids.

Our Sludge Plant Lamella Separator Package

This system is a 2-stream system to handle a peak flow of 10m3/hr (10m3/hr per stream) with a maximum solids load of 500mg/L. Colloides plan included two flocculation tanks upstream of the two Lamella Separator Packages to treat the overall flow on the site. Our full set of 2 stainless steel Lamella Separators, certified to DWI standards were supplied and are mounted within stainless steel tanks. Sludge is collected under the Lamella Settlers in sludge collection hoppers. The sludge is removed from the base of these cones via actuated valves and discharged via gravity and pumped to the sludge holding tanks.

Project Scope Explained

Download our Williamsgate WTW Case Study to read the full list of components for these Lamella Separator Packages and a brief overview of how our systems work.

Environmental Impact Top Priority

The site has been designed to blend in with the natural contours of the surrounding area, and the design also incorporates a green roof to blend seamlessly into the landscape.

“We’ve moved around 300,000m3 of earth to reshape the site and create a deeper valley into which the works sit,” explains Advance Project Manager Stewart Lucas. “Approximately 100,000m3 of that total will be later used as backfill, to bury the treatment water tank and thereby lessen the impact on the landscape.”

One of the pressing issues currently faced by the water industry is incorporating sustainability considerations into design practice and reducing the carbon emissions of energy-intensive processes. Colloides Lamella Separators have been designed with environmental considerations in mind. They greatly increase the clarifier capacity and enable a much greater flow to be treated in the same footprint as conventional clarification. Our design also ensures maximum efficiency in terms of upward flow velocities.

Our Installation Capabilities

Offsite construction is used in many of Colloides projects and offers huge benefits to our clients. Colloides plant was tested and any M&E assemblies and modules were built in a clean and protected manufacturing facility. The plant was then built on site in modular sections to reduce build time, errors and costs. This method also leads to a reduction of waste and quality is greatly improved. One of the most important aspects of this approach is its sustainability due to the reduction in carbon footprint and reduced impact upon local environments.

The Team

Structural Engineer – MWH

Main Contractor – Advance (a joint venture between Balfour Beatty Utilities and MWH)

Lamella System Contractor – Colloide Engineering Systems

Employer – United Utilities

More about this project

https://www.unitedutilities.com/cumbria/our-plans/west-cumbria/williamsgate-water-treatment-works/

https://www.unitedutilities.com/cumbria/our-plans/west-cumbria/west-cumbria-update/

https://www.steelconstruction.info/Williamsgate_Water_Treatment_Works,_Cumbria

Why Choose Colloide?

Colloide Engineering Systems are one of a few Lamella Separator Package (LSP) suppliers that are in the list of Approved Products and Processes for use in Public Water Supply published by the DWI and our systems can be designed in a wide range of sizes and configurations to suit the individual needs of each of our clients. Colloide Lamella Separator systems can be used as standalone arrangements, taking the full plant flow, with or without additional equipment such as sand filters, screens, etc. Learn more about the features and benefits of this technology or view our short video on how Lamella Separator Systems work.