Colloide Engineering Systems designed, supplied and commissioned the Northmoor and Amersham Water Treatment Works (WTW), Lamella Separator packages for SUEZ at Affinity Water drinking water sites. The installation on these sites was completed by CSS (Colloide Site Services).

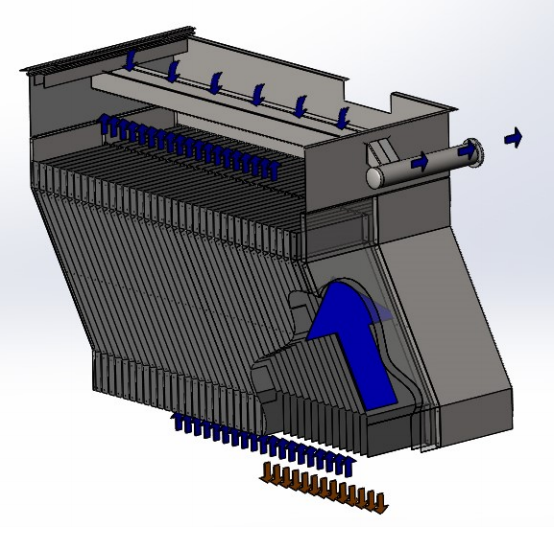

The product includes 2 treatment streams to treat the overall flow of 35m3/hr on both sites, each stream being designed to handle17.5m3/hr. The tanks included connections for level controllers. Chemicals are dosed upstream of the lamella settler system, mixed in line using in line mixers and flocculated using slow speed mixers which are both parts of this package.

Our product included a full set of stainless-steel lamella separators which are certified to DWI standards. These were mounted within stainless steel tanks with flocculation tanks upstream of the settlers. The sludge is collected under the lamella settlers and concentrated up to 2.5% dry solids.

Main Components Explained

Download our Northmoor and Amersham Case Study to read the full list of components for these Lamella Separator Packages and a brief overview of how our systems work.

Customer testimonial

“I would like to thank your team for the speed they installed the plant, their works were carried out with a high level of professionalism. Your team engaged with our site team to achieve this. The team worked to the RAMS and carried out the work to a high standard of H&S. Your team are a credit to your company.” – Mike Carr, Construction Manager at Glan Agua Farrans JV.

Increased Flow and Reduced Footprint

One of the pressing issues currently faced by the water industry is incorporating sustainability considerations into design practice and reducing the carbon emissions of energy-intensive processes. At Colloide, we focus on continued innovation across all our technologies, in order to help work towards these environmental considerations.

Our use of Lamella Separators in a clarifier is a prime example of this. They greatly increase the clarifier capacity and enable a much greater flow to be treated in the same footprint as conventional clarification. Our design also ensures maximum efficiency in terms of upward flow velocities.

Why Choose Colloide?

Colloide Engineering Systems are one of a few Lamella Separator Package (LSP) suppliers that are in the list of Approved Products and Processes for use in Public Water Supply published by the DWI and our systems can be designed in a wide range of sizes and configurations to suit the individual needs of each of our clients. The clarifier can be used as a standalone system, taking the full plant flow, with or without additional equipment such as sand filters, screens, etc. Learn more about the features and benefits of this technology or view our short video on how Lamella Separator Systems work.